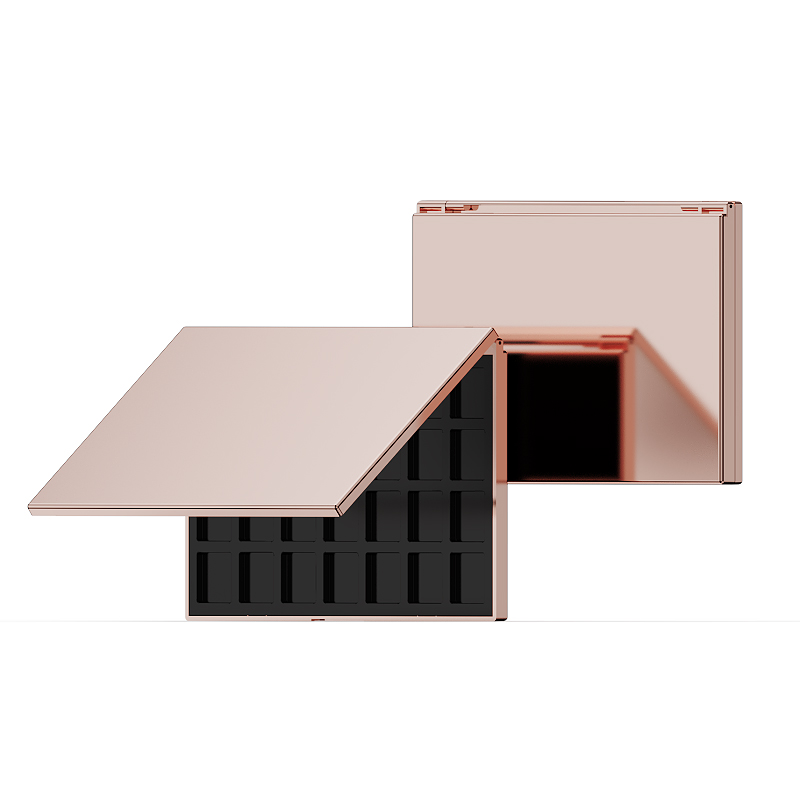

100ml airless pump bottle for cosmetic

Product Introduction

Our 100ml Airless Pump Bottle for Cosmetic is meticulously designed and manufactured to meet your highest requirements. Its highlights and advantages are as follows:

Superior Quality: The product is certified to strict US and EU standards, ensuring reliability and meeting hygiene requirements.

Unique Design: The sleek and elegant appearance captures attention, enhancing your brand image and setting you apart in the market.

Affordable Price: Compared to major brands on the market, our price is highly competitive, helping you save costs and boost profits.

3.High-Quality Materials: We use durable, high-quality plastic PET materials to ensure product stability and a long lifespan.

Airless Pump Design: Utilizing airless pump technology prevents air contamination, extending the product's shelf life and reducing waste.

Reusable: Users can reuse the product, enhancing customer satisfaction and reducing environmental impact.

Customization Options: We offer various color and label customization choices to meet the personalized needs of different customers.

Application

Our 100ml Airless Pump Bottle for Cosmetic is suitable for various cosmetics and skincare products, including creams, lotions, and serums. It is the ideal choice for cosmetic brands, beauty salons, and personal care product suppliers. The airless pump technology ensures product hygiene during use, prolonging the product's lifespan.

Production Process

Detailed Description of the Production Process for 100ml Vacuum Bottles to Help Customers Understand How this Product is Manufactured:

1. Material Procurement: The first step in the production process is the procurement of high-quality PET and PP raw materials. We select durable, food-grade plastic materials to ensure product quality and sustainability.

2. Mold Material Preparation: Molds and components undergo precision cutting and processing to ensure they meet product specifications and requirements. This includes cutting plastic sheets to create bottle bodies and pump heads, among other components.

3. Injection Molding: The next step in manufacturing the bottle bodies and other components is injection molding. Raw materials are injected into the molds at high temperatures to form the basic shape of the bottle. This requires precise temperature and pressure control to ensure product consistency and quality.

4. Assembly Process: Once the individual components are manufactured, our technical team conducts the assembly process. This includes assembling pump heads, pipelines, pistons, and other components with the bottle bodies.

5. Inspection and Quality Control: At various stages of the production process, we conduct rigorous inspection and quality control to ensure that each product meets high-quality standards. This includes visual inspections, dimension measurements, and functional testing.

6. Sanitization: After product assembly is complete, we perform thorough cleaning and sanitization to ensure the products are sterile before being delivered to customers.

7. Packaging: Products are packaged in accordance with international transportation and storage standards to ensure that they remain undamaged during transport and storage.

8. Final Inspection: Before leaving the factory, we perform a final inspection to ensure that the products have no defects. This includes checking sealing performance, proper operation of the pump head, and visual quality.

9. Delivery: Once the products pass the final inspection, they are prepared for delivery to customers. We use safe transportation methods to ensure that products are not damaged during transit.

Our production process is subject to strict control and supervision to ensure that every 100ml airless bottle meets high-quality, consistency, and hygiene standards. Our independent technical team is constantly dedicated to employing the latest technology and processes to ensure that our products always remain at the forefront of the industry.